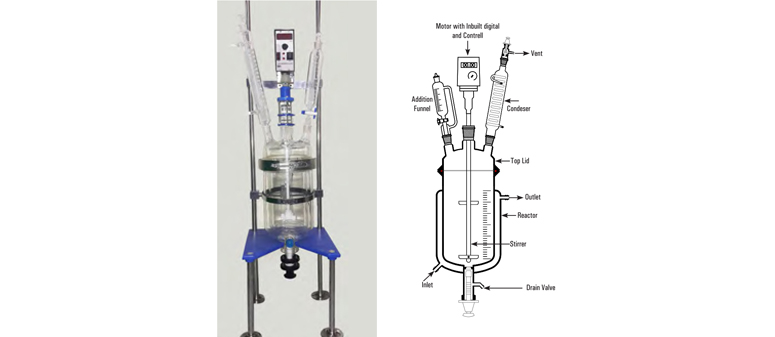

Benchtop Lab Reactor

In addition to range of glassware, we also supply Benchtop Lab Glass Reactors. This includes small vessels (single, double or triple walled) from 0.5 L to 5 L. In addition we have all the glass components you are likely to need such as condensers, receivers, addition funnels, reflux dividers etc

Our Benchtop Lab Glass Reactors include easy accessibility through open support frame, manufactured from German made Borosilicate glass and a minimal dead space with many other standard and optional features.

Key Specifications

- Reactor Volume: 0.5 L to 5 L

- Reactor Type: Single Wall, Double Walled & Triple Walled

- Operating Pressure: Full Vacuum to 0.5 bar (g)

- Operating Temperature: -50°C to +180°C

- Gear Motor with Inbuilt Digital Indicator Speed Range 40 to 400 RPM

- Thermal Shock Resistance: (Dt): 60°C for Triple Walled and 110°C for Double Walled Reactors.

- Standard GL Threads for Inlet and Outlet. (Inlet and Outlet can be supplied with beaded process pipe.)

| Unit Cat. Ref. | Addition Funnel (mL) | Condenser Length | LxBxH |

|---|---|---|---|

| BLR 0.5 (100DN) | 200 | 300 | 250X250X900 |

| BLR1 (100DN) | 250 | 300 | 250X250X900 |

| BLR 2 (100DN) | 500 | 300 | 250X250X1350 |

| BLR 3 (150DN) | 500 | 300 | 250X250X1450 |

| BLR 5 (150DN) | 500 | 400 | 350X350X1450 |

SALIENT FEATURES

- Reactors equipped with the flush bottom valve of the special type to ensure leak-free sealing over entire temperature range.

- All reactors are designed to keep L/ID Ratio within 1.5(max) for performance and easy scale up. L/ID ratio may be changed on request.

- All These Reactors are designed GMP.

- Manufacture from German Raw Material.

- Ideal for benchtop fume hoods.(SS/MS)

- Stirrer with suitable seal (Mechanical, Stuffing Box, Magnetic Seal, High Vacuum Stuffing Box).

- Skid mounted and quick release coupling for ease of installation and dismantling.

- Overhead stirrer motor with built-in speed controller and display

- Interchangeable Stirred (Anchor/Propeller/Turbine) as per your suitability

OPTIONAL

- Vacuum Pump

- Digital Temp Indicator

- Chiller

- Heating/Cooling System

- Hot Water/Oil circulator

- Mobility Support

TECHNICAL INFORMATION

Laboratory works require apparatus made in a Borosilicate 3.3 expansion glass which offers maximum inertness to widest range of chemical substances, withstand thermal shock, high temperature without deforming and resilient enough to withstand the normal laboratory handling, washing and sterilizing processes.

Borosilicate glass represents unmatched standardized glass for construction of Laboratory Glasswares. Its stadily growing use is due to many advantages over conventional materials.

- Outstanding corrosion resistance

- Smooth pore and surface.

- Transparency

- Catalytic, inertness

- No effect on taste and odour

- Physiological inertness

Borosilicate glass is chosen for its unique chemical and physical properties. Borosilicate glass can be considered as being composed of Oxides. Silica (Six), Boron oxide (Bg) and Phosphorous Pentaoxide (gg ) are chief glass form Oxides. Soda (Nag), Lime ( CaO ), Alumina (Alg )3 otash (KO} Magnesia (MgO) and Lead Oxide (Pb0) are the principle modifiers/fluxes.

CHEMICAL COMPOSITION

The composition of borosilicate glass used has following approximate composition

- Si0,- 80.6 % B,03 12.5%

- Nag - 4.5 % AI,Ot 2.2 %

RESISTANCE TO CHEMICALS

Borosilicate glass is inert to almost all materials except hydrofluoric acid (HF) phosphoric acid (HPO/ and hot strong caustic solutions. Of these, Hydrofluoric acid has the most serious effect, even when it is present in PPM (parts per million) in solutions, Whereas phosphoric acid and caustic solutions cause no problems when cold but at elevated temperature corrosion occurs. In case of caustic solutions upto 30% concentration can be handled safely at ambient temperature.

Under actual operating conditions, the effect of turbulance, and traces of other chemicals in the solution may increase or decrease the rate of attack.Thus, corrosion by caustic solutions can not be predefine.

THERMAL PROPERTIES

Linear coefficient of thermal expansion of borosilicate glass over the temperature 0-3@ C is 3.3 x 10 C. This is very low when compared with other glasses and metals. That is why borosilicate glass is often called low expansion borosilicate glass

SPECIFIC HEAT

Specific heat between 28C and 3009 is average to be 0.233 Kcal/K§ C.

THERMAL CONDUCTIVITY

Thermal conductivity is 1.0 Kcal/hr. DC over the permissible operating temperature range

ANNEALING

Annealing of glass is the process where the glass is heated and kept for a defined period of time to relieve internal stresses. Careful cooling under controlled conditions is essential to ensure that no stresses are reintroduced by chilling/cooling.

MECHANICAL PROPERTIES

The lack of ductility of glass prevents the equalization of stresses at local irregularities or flaws and the breakage strength varies considerably about a mean value. This latter is found to occur at a tensile strength of about 700 kg/crrf.

In order to allow for the spread of breaking stress, a large factor of safety is applied when determining the wall thickness requirement to allow operation up to specified limit of working pressure.

OPTICAL PROPERTIES

Borosilicate glass shows no appreciable absorption in the visible region of spectrum and therefore appears clear and colorless. In photo chemical process the transparency of ultra violet is of particular importance. It follows from the transmittance of material in UV region that photochemical reactions such as chlorination & sulphochlorination can be performed in it.

Spares & Accessories

| Sr. | Description | MOC | Unit Size | CAT REF |

|---|---|---|---|---|

| Single Wall Vessel | ||||

| 1 | Jacketed Vessel - 0.5 | Duran | 0.5 L | VZ0.5/J |

| 2 | Jacketed Vessel -1.0 L | Duran | 1.0 L | VZ1/J |

| 3 | Jacketed Vessel - 2.0 L | Duran | 2.0 L | VZ2/J |

| 4 | Jacketed Vessel - 3.0 L | Duran | 3.0 L | VZ3/J |

| 5 | Jacketed Vessel - 5.0 L | Duran | 5.0 L | VZ5/J |

| Flexi - Double Wall Jacketed Vessel | ||||

| 1 | Jacketed Vessel - 0.5 | Duran | 0.5 L | VZD0.5/J |

| 2 | Jacketed Vessel -1.0 L | Duran | 1.0 L | VZD1/J |

| 3 | Jacketed Vessel - 2.0 L | Duran | 2.0 L | VZD2/J |

| 4 | Jacketed Vessel - 3.0 L | Duran | 3.0 L | VZD3/J |

| 5 | Jacketed Vessel - 5.0 L | Duran | 5.0 L | VZD5/J | Flexi - Tripple Wall Jacketed Vessel |

| 1 | Jacketed Vessel - 0.5 | Duran | 0.5 L | VZT0.5/J |

| 2 | Jacketed Vessel -1.0 L | Duran | 1.0 L | VZT1/J |

| 3 | Jacketed Vessel - 2.0 L | Duran | 2.0 L | VZT2/J |

| 4 | Jacketed Vessel - 3.0 L | Duran | 3.0 L | VZT3/J |

| 5 | Jacketed Vessel - 5.0 L | Duran | 5.0 L | VZT5/J | Vessel Cover |

| 1 | Vessel Cover - 4” C -B24, S-B24 X B24 at 10°, S-B19 X B19 at 10° | Duran | 0.5 L - 2.0 L | VZA4/J |

| 2 | Vessel Cover - 6”,C -B34, S-B24 X B24 at 10°, S-B19 X B19 at 10° | Duran | 3.0 L- 5.0 L | VZA6/J | Coupling & Gasket |

| 1 | Quick Release Coupling 4" | SS304 | 0.5 L- 2.0 L | QCT4/J |

| 2 | Quick Release Coupling 6" | SS304 | 3.0 L- 5.0 L | QCT6/J |

| 3 | SS 304 Coupling 1" with SS 304 Nuts & Bolts | SS304 | 0.5 L- 2.0 L | CT1/SS |

| 4 | PTFE 'O' Ring for 1" | PTFE | 3.0 L- 5.0 L | TR1 |

| 5 | SS 304 Coupling 1.5” with SS 304 Nuts & Bolts | SS304 | 3.0 L- 5.0 L | CT1.5/SS |

| 6 | PTFE ’0’ Ring for 1.5” | PTFE | 0.5 L- 5.0 L | TR1.5 | Valve |

| 1 | Flush Bottom Valve -1” | Duran | 0.5 L-2.0 L | BAL1/J |

| 2 | Flush Bottom Valve -1.5" | Duran | 3.0 L- 5.0 L | BAL1.5/J | PTFE Stirrer (Blade) |

| 1 | SR - A (Blade/Propeller/Turbine) | 400 mm | 0.5 L- 2.0 L | STB4 |

| 2 | SR - B (Blade/Propeller/Turbine/Anchor) | 550 mm | 3.0 L - 5.0 L | STB5 | Sealing |

| 1 | High Vacuum Stuffing Box | PTFE | 0.5 L-2.0 L | HSB24 |

| 2 | High Vacuum Stuffing Box | PTFE | 0.3 L - 5.0 L | HSB34 | Stirrer Drive |

| 1 | Lab Strirere Drive Speed 40 to 400 RPM with dig. Indicator | MS | 0.5 L- 5.0 L | LSD | Sensor |

| 1 | Temperature Indiacator senser -40° to 250° c | MS | 0.5 L - 5.0 L | LTI | Glass Accessories |

| 1 | Double Coil Condensor with Cone B24, socket B24, 300 mm long | Borosilicate 3.3 | 0.5 L- 3.0 L | HES24 |

| 2 | Double Coil Condensor with Cone B24, socket B24, 400 mm long | Borosilicate 3.3 | 5.0 L | HEC4S |

| 3 | 250 ml Funnel, Additional /Dropping, with socket B19/24 cylindrical, St bore PTFE stop cock, graduated pressure equializing | Borosilicate 3.3 | 0.5 L-1.0 L | AEF25 |

| 4 | 500 ml Funnel, Additional / Dropping,with socket B24/25 cylindrical, St bore PTFE stop cock, graduated pressure equializing | Borosilicate 3.3 | 2.0 L- 5.0 L | AEF50 |

| 5 | Thermometer Pocket B19 | Borosilicate 3.3 | 0.5 L | TP0.5 |

| 6 | Thermometer Pocket B19 | Borosilicate 3.3 | 1.0 L | TP1 |

| 7 | Thermometer Pocket B19 | Borosilicate 3.3 | 2.0 L | TP2 |

| 8 | Thermometer Pocket B24 | Borosilicate 3.3 | 3.0 L | TP3 |

| 9 | Thermometer Pocket B24 | Borosilicate 3.3 | 5.0 L | Tp5 | Scaffolding / Stand |

| 1 | SS 304 Scaffolding / Stand for 0.5 L to 2 L | SS 304 | 0.5 L- 2.0 L | TBG/ SS/ 0.5-2/J |

| 2 | SS 304 Scaffolding / Stand for 3 L to 5 L | SS 304 | 3.0 L- 5.0 L | TBG/ SS/ 3-5/J |

Myth

It is often considered that, glass articles are easy to manufacture. Melt the glass and cast.

Fact

At Surya, we manufacture glass articles and equipment from glass tubes of various sizes and thicknesses

The glass tubes are heated to the temperature of 800 - 1200 deg. C Like Blacksmith, shaped it like Potter with precision like goldsmith.

BEAKERS

2111 BEAKERS GRIFFIN, LOW FORM, WITH SPOUT, GRADUATED

| CAT.REF | CAP.ML. | APPROX. O.D.MM | APPROX. HEIGHTMM | PACKING I/C/M |

|---|---|---|---|---|

| 2111/32 | 5000 | 170 | 270 | 0/3/9 |

| 2111/35 | 10000 | 220 | 322 | 0/1/6 |

| 2111/40 | 20000 | 290 | 400 | 0/1/2 |

BOTTLES

2351 BOTTLES, ASPIRATOR WITH OUTLET FOR STOPPER

| Cat.Ref. | CAP. ML. | APPROX O.D. MM | APPROX HEIGHT MM | APPROX NECK I.D MM | APPROX OUTLET I.D. MM | QTY PER CASE |

|---|---|---|---|---|---|---|

| 2351/32 | 5000 | 190 | 320 | 44 | 28 | 1 |

| 2351/35 | 10000 | 220 | 420 | 54 | 28 | 1 |

| 2351/40 | 20000 | 300 | 535 | 54 | 28 | 1 |

2356 BOTTLES, ASPIRATOR , WITH INTERCHANGEABLE STOPPER AND STOPCOCK

| Cat.Ref. | CAP. ML. | APPROX O.D. MM | APPROX HEIGHT MM | APPROX NECK I.D MM | APPROX OUTLET I.D. MM | QTY PER CASE |

|---|---|---|---|---|---|---|

| 2356/32 | 5 000 | 190 | 320 | 45/40 | 29/32 | 1 |

| 2356/35 | 10000 | 220 | 420 | 55/44 | 29/32 | 1 |

| 2356/40 | 20000 | 300 | 535 | 55/44 | 29/32 | 1 |

2610 BOTTLES, REAGENT, AMBER, NARROW MOUTH WITH INTERCHANGEABLE FLAT HEAD STOPPER

| Cat.Ref. | CAP. ML. | APPROX O.D. MM | APPROX HEIGHT MM | SIZE OF INTERCHA- -NGEABLE STOPPER | PACKING I/C/M |

|---|---|---|---|---|---|

| 2610/32 | 5000 | 190 | 320 | 45/40 | 1/0/9 |

| 2610/35 | 10000 | 220 | 420 | 55/44 | 0/1/2 |

| 2610/40 | 20000 | 300 | 535 | 55/44 | 0/1/2 |

2611 BOTTLES, REAGENT, PLAIN NARROW MOUTH, WITH INTERCHANGEABLE FLAT HEAD STOPPER

| Cat.Ref. | CAP. ML. | APPROX O.D. MM | APPROX HEIGHT MM | SIZE OF INTERCHA- -NGEABLE STOPPER | PACKING I/C/M |

|---|---|---|---|---|---|

| 2611/32 | 5000 | 190 | 320 | 45/40 | 1/0/9 |

| 2611/35 | 10000 | 220 | 420 | 55/44 | 0/1/2 |

| 2611/40 | 20000 | 300 | 535 | 55/44 | 0/1/2 |

2612 BOTTLES, REAGENT , SCREW CAP, PLAIN -WITH GL45 (WITH CLASS-A CERTIFICATE)

| Cat.Ref. | CAP. ML. | APPROX O.D. MM | APPROX HEIGHT MM | APPROX. NACK I.D. MM | PACKING I/C/M | |

|---|---|---|---|---|---|---|

| 2612/32/45 | 5000 | 190 | 320 | 44 | 1/2/12 | |

| 2612/35/45 | 10000 | 220 | 420 | 54 | 0/1/2 | |

| 2612/40/45 | 20000 | 300 | 535 | 54 | 0/1/2 | |

| 2612/45/45 | 50000 | 54 | 0/1/1 |

2613 BOTTLES, REAGENT , SCREW CAP , AMBER -WITH GL45 (WITH CLASS-A CERTIFICATE)

| Cat.Ref. | CAP. ML. | APPROX O.D. MM | APPROX HEIGHT MM | APPROX. NACK I.D. MM | PACKING I/C/M | |

|---|---|---|---|---|---|---|

| 2613/32/45 | 5000 | 190 | 320 | 44 | 1/2/12 | |

| 2613/35/45 | 10000 | 220 | 420 | 54 | 0/1/2 | |

| 2613/40/45 | 20000 | 300 | 535 | 54 | 0/1/2 | |

| 2613/45/45 | 50000 | 54 | 0/1/1 |

2614 BOTTLES, REAGENT , SCREW CAP , PLAIN -WITH GL80 (WITH CLASS-A CERTIFICATE)

| Cat.Ref. | CAP. ML. | APPROX O.D. MM | APPROX HEIGHT MM | APPROX. NACK I.D. MM | PACKING I/C/M | |

|---|---|---|---|---|---|---|

| 2614/32/80 | 5000 | 190 | 380 | 44 | 1/2/12 | |

| 2614/35/80 | 10000 | 220 | 465 | 54 | 0/1/2 | |

| 2614/40/80 | 20000 | 300 | 580 | 54 | 0/1/2 | |

| 2614/45/80 | 50000 | 400 | 600 | 54 | 0/1/1 |

2615 BOTTLES, REAGENT , SCREW CAP , AMBER -WITH GL80 (WITH CLASS-A CERTIFICATE)

| Cat.Ref. | CAP. ML. | APPROX O.D. MM | APPROX HEIGHT MM | APPROX. NACK I.D. MM | PACKING I/C/M | |

|---|---|---|---|---|---|---|

| 2615/32/80 | 5000 | 190 | 380 | 44 | 1/2/12 | |

| 2615/35/80 | 10000 | 220 | 465 | 54 | 0/1/2 | |

| 2615/40/80 | 20000 | 300 | 580 | 54 | 0/1/2 | |

| 2615/45/80 | 50000 | 400 | 600 | 54 | 0/1/1 |

2690 BOTTLES, SOLUTION , AMBER, TOOLED NECK

| Cat.Ref. | CAP. ML. | APPROX O.D. MM | APPROX HEIGHT MM | APPROX. NACK I.D. MM | PACKING I/C/M |

|---|---|---|---|---|---|

| 2690/32 | 5000 | 190 | 320 | 44 | 1/2/12 |

| 2690/35 | 10000 | 220 | 420 | 54 | 0/1/2 |

| 2690/40 | 20000 | 300 | 535 | 54 | 0/1/2 |

2696 BOTTLES, SOLUTION, PLAIN TOOLED NECK

| Cat.Ref. | CAP. ML. | APPROX O.D. MM | APPROX HEIGHT MM | APPROX. NACK I.D. MM | PACKING I/C/M |

|---|---|---|---|---|---|

| 2696/32 | 5000 | 190 | 320 | 44 | 1/2/12 |

| 2696/35 | 10000 | 220 | 420 | 54 | 0/1/2 |

| 2696/40 | 20000 | 300 | 535 | 54 | 0/1/2 |

Myth

Glass is Fragile and shall be avoided.

Fact

Glass being fragile cannot be eliminated from the use and is mainly used for its characteristics like (Purity, Non-Corrosive, non-reactivity, transparency, rich look, appearance, etc.).

Fragility of glass depends on physical impact force.

- Physical Impact force is dependent on the handling and a little care can nullify it.

- Tensile strength of glass is weak. This can be enhanced by increasing the thickness of the item and thermal/chemical toughening process.

- Glass has magnificent compressive strength. If a glass is given compressive pressure in between Mo metallic flanges, under extreme pressure, the glass will remain intact and the metallic flange or the studs may break due to repulsive force. (Request for Demo).

DESICCATORS

4192 DESICCATORS WITH COVER, KNOB TOP

| Cat.Ref. | SIZE MM | GROUND FLANGE APPROX. I.D. MM | PACKING I/C/M |

|---|---|---|---|

| 4192/01 | 100mm | 105 | 0/1/- |

| 4192/02 | 150mm | 154 | 1/2/12 |

| 4192/03 | 200mm | 202 | 0/1/6 |

| 4192/04 | 250mm | 260 | -/1/- |

| 4192/05 | 300mm | 300 | -/1/- |

| 4192/06 | 500mm | 500 | -/1/- |

4220’ DESICCATORS VACUUM, WITH TABULATED COVER, STOPPER, WITH PTFE SPINDLE

| Cat.Ref. | SIZE MM | GROUND FLANGE APPROX. I.D. MM | INTER- -CHANGABLE JOINT SIZE | PACKING I/C/M |

|---|---|---|---|---|

| 4220/01 | 100mm | 105 | 29/32 | 0/1/- |

| 4220/02 | 150mm | 154 | 29/32 | 1/2/12 |

| 4220/03 | 200mm | 202 | 29/32 | 0/1/6 |

| 4220/04 | 250mm | 260 | 29/32 | -/1/- |

| 4220/05 | 300mm | 300 | 29/32 | -/1/- |

| 4220/06 | 500mm | 500 | 34/35 | -/1/- |

Vacuum type Desiccators, when ground surface is cleaned & greased, will hold a vacuum of 500 mm of Mercury (Hg) over a 24 hours period.

MICRO FILTER ASSEMBLY

4399 MICRO FILTER HOLDER ASSEMBLY, WITH GROUND GLASS JOINT

| Cat.Ref. | COMPONENTS | Qty Per Case |

|---|---|---|

| 4399/47 | Funnel for 47 size filter base with sintered disc for 34/35 size socket in the stem for 47 size filter spring clamp, 47 size 1000 ml. buchner flask with 34/35 cone | 1 |

4396 MICRO FILTER HOLDER ASSEMBLY, WITH RUBBER CORK

| Cat.Ref. | COMPONENTS | Qty Per Case |

|---|---|---|

| 4396/13 | Funnel for 13 & 25 size filter base with sintered disc for 13 size filter spring clamp, 13 & 25 size 100 ml. buchner flask with cork | 1 |

| 4396/25 | Funnel for 13 & 25 size filter base with sintered disc for 25 size filter spring clamp, 13 & 25 size 100 ml. buchner flask with cork | 1 |

| 4396/47 | Funnel for 47 size filter base with sintered disc for 47 size filter spring clamp, 47 size 1000 ml. buchner flask with cork | 1 |

4951 COMPLETE EXTRACTION APPARATUS

| Cat.Ref. | CAP. ML. | FLASH SIZE ML | QTY. PER CASE |

|---|---|---|---|

| 4951/29 | 2000 | 5000 | 1 |

| 4951/32 | 5000 | 10000 | 1 |

| 4951/35 | 10000 | 20000 | 1 |

FLASKS

5171 FLASKS, BOILING, FLORENCE, FLAT BOTTOM

| Cat.Ref. | CAP. ML. | APPROX. O.D. MM | APPROX. HEIGHT MM | APPROX. NECK O.D. MM | PACKING I/C/M |

|---|---|---|---|---|---|

| 5171/32 | 5000 | 223 | 340 | 60 | 1/0/9 |

| 5171/35 | 10000 | 285 | 400 | 60 | 0/2/4 |

| 5171/40 | 20000 | 350 | 505 | 70 | 0/1/4 |

5371 FLASKS, BOILING, ROUND BOTTOM

| Cat.Ref. | CAP. ML. | APPROX. O.D. MM | APPROX. HEIGHT MM | APPROX. NECK O.D. MM | PACKING I/C/M |

|---|---|---|---|---|---|

| 5371/32 | 5000 | 223 | 350 | 60 | 1/0/9 |

| 5371/35 | 10000 | 285 | 420 | 60 | 0/2/4 |

| 5371/40 | 20000 | 350 | 505 | 70 | 0/1/4 |

5441 (VESSELS) REACTION, WIDE MOUTH, FLAT FLANGE 100mm I.D., 150 mm O.D.

| Cat.Ref. | CAP. ML. | APPROX. HEIGHT MM | PACKING I/C/M |

|---|---|---|---|

| 5441/32 | 5000 | 260 | 1/0/9 |

| 5441/35 | 10000 | 320 | 0/2/4 |

| 5441/40 | 20000 | 400 | 0/1/4 |

5442 LIDS, FOR FLASKS REACTION CAT. NO.5441. FLAT FLANGE AND INTERCHANGEABLE JOINT

| Cat.Ref. | INTERCHANGEABLE JOINT SIZE | SIDE 5° | SIDE 10° | SIDE 15° | QTY. PER CASE | |

|---|---|---|---|---|---|---|

| CENTER | PARALLEL | |||||

| 5442/1924 | 19/26 | 19/26 | 24/29 | 19/26 | - | 2 |

| 5442/1914 | 19/26 | 14/23 | 14/23 | 14/23 | 29/32 | 2 |

| 5442/2914 | 29/32 | 14/23 | 14/23 | 14/23 | 29/32 | 2 |

| 5442/1934 | 19/26 | 19/26 | 19/26 | 19/26 | 34/35 | 2 |

| 5442/2434 | 24/29 | 19/26 | 19/26 | 19/26 | 34/35 | 2 |

5491 FLASKS, BOILING, ROUND BOTTOM, SHORT NECK WITH INTERCHANGEABLE JOINT

| Cat.Ref. | CAP ML | INTER CHANGE- -ABLE JOINT | APPROX O.D. MM | APPROX HEIGHT MM | PACKING I/C/M |

|---|---|---|---|---|---|

| 5491/32 | 5000 | 34/35 | 223 | 300 | 1/0/9 |

| 5491/35 | 10000 | 55/44 | 285 | 385 | 0/2/4 |

| 5491/40 | 20000 | 55/44 | 350 | 435 | 0/1/4 |

5494 FLASKS, ROUND BOTTOM, THREE NECKS, CENTRE NECK AND TWO ANGLED SIDE NECKS WITH INTERCHANGEABLE JOINT

| Cat.Ref. | CAP. ML | INTERCHANGEABLE JOINT SIZE | APPROX. HEIGHT MM | Qty. Per Case | ||

|---|---|---|---|---|---|---|

| CENTRE NECK | SIDE NECK | SIDE NECK | ||||

| 5494/32 | 5000 | 34/35 | 24/29 | 24/29 | 350 | 1 |

| 5494/35 | 10000 | 34/35 | 24/29 | 24/29 | 420 | 1 |

| 5494/40 | 20000 | 55/44 | 24/29 | 24/29 | 500 | 1 |

5495 FLASKS, ROUND BOTTOM, THREE NECKS, CENTRE NECK AND TWO PARALLEL SIDE NECKS WITH INTERCHANGEABLE JOINT

| Cat.Ref. | CAP. ML | INTERCHANGEABLE JOINT SIZE | APPROX. HEIGHT MM | Qty. Per Case | ||

|---|---|---|---|---|---|---|

| CENTRE NECK | SIDE NECK | SIDE NECK | ||||

| 5495/32 | 5000 | 34/35 | 24/29 | 24/29 | 350 | 1 |

| 5495/35 | 10000 | 34/35 | 24/29 | 24/29 | 420 | 1 |

| 5495/40 | 20000 | 55/44 | 24/29 | 24/29 | 500 | 1 |

5496 FLASKS, ROUND BOTTOM, FOUR NECKS, CENTRE NECK AND THREE ANGLED SIDE NECKS WITH INTERCHANGEABLE JOINT

| Cat. Case Ref. | CAP. ML | INTERCHANGEABLE JOINT SIZE | APPROX. HEIGHT MM | Qty. Per Case | |||

|---|---|---|---|---|---|---|---|

| Center NECK | SIDE NECK | SIDE NECK | SIDE NECK | ||||

| 5496/32 | 5000 | 34/35 | 24/29 | 24/29 | 24/29 | 350 | 1 |

| 5496/35 | 10000 | 34/35 | 24/29 | 24/29 | 24/29 | 420 | 1 |

| 5496/40 | 20000 | 55/44 | 24/29 | 24/29 | 24/29 | 500 | 1 |

5497 FLASKS, ROUND BOTTOM, FOUR NECKS, CENTRE NECK AND THREE PARALLEL SIDE NECKS WITH INTERCHANGEABLE JOINT

| Cat. Case Ref. | CAP. ML | INTERCHANGEABLE JOINT SIZE | APPROX. HEIGHT MM | Qty. Per Case | |||

|---|---|---|---|---|---|---|---|

| CENTER NECK | SIDE NECK | SIDE NECK | SIDE NECK | ||||

| 5497/32 | 5000 | 34/35 | 24/29 | 24/29 | 24/29 | 350 | 1 |

| 5497/35 | 10000 | 34/35 | 24/29 | 24/29 | 24/29 | 420 | 1 |

| 5497/40 | 20000 | 55/44 | 24/29 | 24/29 | 24/29 | 500 | 1 |

5091 FLASKS, ERLENMEYER, GRADUATED, CONICAL, NARROW MOUTH

| Cat.Ref. | CAP. ML | APPROX. O.D. MM. | APPROX. HEIGHT MM | APPROX. O.D. NECK MM | PACKING I/C/M |

|---|---|---|---|---|---|

| 5091/32 | 5000 | 220 | 377 | 50 | 0/2/4 |

| 5091/35 | 10000 | 280 | 450 | 60 | 0/1/2 |

| 5091/40 | 20000 | - | - | - | 0/1/1 |

6451 FLASKS, FILTERING, HEAW WALL, BOLT NECK WITH TUBULATION

| Cat.Ref. | CAP. ML | APPROX. O.D. MM. | APPROX. HEIGHT MM | PACKING I/C/M |

|---|---|---|---|---|

| 6451/32 | 5000 | 237 | 450 | 0/1/2 |

| 6451/35* | 10000 | 220 | 500 | 0/1/2 |

| 6451/40” | 20000 | 300 | 560 | 0/1/2 |

Myth

Glass is just for windows

Fact

There is so much more to glass with endless possibilities. There are different types of glass that have various uses in all fields from Technology to Architecture.

While windows are still a primary application for glass in your home, scientists are currently manipulating glass at the molecular level in the hopes of increasing the total capabilities of glass products. In addition, expanding glass’ capabilities helps to solve some of the world’s toughest issues.

Scientists have experimented with glass that makes high-speed communication possible through optical fibre.

Innovations in glass products also help turn solar energy into electricity and enable thinner, lighter, and more durable display devices.

FILTER FLASK

Surya Scientific is a leading Industrial and Laboratory Glassware manufacturing company in India. Since inception, our moto has been to go beyond possible to delight customer through innovation

Under vacuum environment, the filtration flask are prone to collapse and thus we are proud to introduce new design of Filter Flask. These filtration flasks are manufactured as per Japanese design and are more suitable and stronger as compared to existing conventional/traditional available designs

Application

- Filtering solutions

- Removing solvent under reduced pressure.

- Provides buffer/trap to secure pump or vacuum line.

Salient Features :

- Thick wall of the flask provides it the strength to withstand the pressure difference while holding a vacuum inside.

- Side arm/nozzle to connect to a vacuum pump or aspirator, to create/lower vacuum/pressure inside the flask.

- Made from Borosilicate glass 3.3, to provide visibility, strength, heating and chemical resistance.

6451 / J JAPAN FLASKS, FILTERING, HEAVY WALL

| Cat.Ref. | CAP. ML. | APPROX O.D. MM | APPROX HEIGHT MM | PACKING I/C/M |

|---|---|---|---|---|

| 6451/29/J | 2000 | 170 | 240 | 0/6/24 |

| 6451/30/J | 3000 | 200 | 295 | 0/1/6 |

| 6451/32/J | 5000 | 240 | 340 | 0/1/2 |

| 6451/35/J | 10000 | 300 | 420 | 0/1/2 |

| 6451/40/J | 20000 | 350 | 530 | 0/1/16 |

FUNNELS

7451 FUNNELS, SEPARATING, GLOBE SHAPE, WITH ROTOFLOW STOPCOCK WITH HOLLOW INTERCHANGEABLE STOPPER

| Cat.Ref. | CAP. ML | I / C STOPPER SIZE | PACKING I/C/M |

|---|---|---|---|

| 7451/32 | 5000 | 34/25 | -/1/- |

| 7451/35 | 10000 | 34/25 | -/1/- |

| 7451/40 | 20000 | 45/40 | -/1/- |

7513 FUNNELS, SEPARATING, PEAR SHAPE, WITH ROTOFLOW STOPCOCK HOLLOW INTERCHANGEABLE STOPPER

| Cat.Ref. | CAP. ML | I / C STOPPER SIZE | PACKING I/C/M |

|---|---|---|---|

| 7513/32 | 5000 | 34/25 | -/1/- |

| 7513/35 | 10000 | 34/25 | -/1/- |

| 7513/40 | 20000 | 45/40 | -/1/- |

7514 FUNNELS SEPARATING, PEAR SHAPE, FITTED WITH PTFE KEY STOPCOCK WITH INTERCHANGEABLE HOLLOW STOPPER

| Cat.Ref. | CAP. ML | I / C STOPPER SIZE | PACKING I/C/M |

|---|---|---|---|

| 7514/32 | 5000 | 34/25 | -/1/- |

| 7514/35 | 10000 | 34/25 | -/1/- |

| 7514/40 | 20000 | 45/40 | -/1/- |

JARS

7900 MUSEUM JARS

| Cat.Ref. | O.D. X HEIGHT MM | QTY. PER CASE |

|---|---|---|

| 7900/1 | 80 x 200 | 4 |

| 7900/2 | 80 x 250 | 4 |

| 7900/3 | 100 x 200 | 4 |

| 7900/4 | 100 x 250 | 4 |

| 7900/5 | 100 x 300 | 4 |

| 7900/6 | 150 x 200 | 2 |

| 7900/7 | 150 x 250 | 2 |

| 7900/8 | 150 x 300 | 2 |

| 7900/9 | 225 x 250 | 1 |

| 7900/10 | 225 x 300 | 1 |

| 7900/11 | 225 x 375 | 1 |

| 7900/12 | 300 x 300 | 1 |

| 7900/13 | 300 x 375 | 1 |

| 7900/14 | 300 x 450 | 1 |

7997 JARS, BELL, ROUND BOTTOM, EDGE GROUND

| Cat.Ref. | APPROX CAP. LTR | APPROX HEIGHT MM | APPROX O.D. MM | QTY. PER CASE |

|---|---|---|---|---|

| 7997/39 | 19 | 450 | 315 | 1 |

| 7997/38 | 17 | 400 | 315 | 1 |

| 7997/33 | 6 | 350 | 230 | 1 |

7016 JARS, CYLINDRICAL, FERMENTATION

| Cat.Ref. | APPROX CAP. LTR | APPROX HEIGHT MM | APPROX O.D. MM | QTY. PER CASE |

|---|---|---|---|---|

| 7016/35 | 10 | 320 | 230 | 1 |

| 7016/37 | 14 | 455 | 230 | 1 |