A wide variety of valves are described in this section. All the valves are made of Borosilicate Glass body & PTFE plug so that process fluid just comes in contact with Glass & PTFE only. Borosilicate Glass body permits the visual checking of the operation.

All the valves are suitable for operation under full vacuum conditions & a maximum temperature of 200'C

Borosilicate Valves are available from DN15 to DN50.

Bigger size valves are available on request.

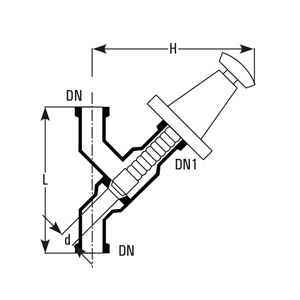

STRAIGHT THROUGH VALVES

| Cat.Ref. | DN | DN1 | d | L | H |

|---|---|---|---|---|---|

| PV0.5 | 12 | 12 | 10 | 125 | 125 |

| PV0.7 | 15 | 15 | 10 | 125 | 125 |

| PV1* | 25 | 25 | 18 | 175 | 175 |

| PV1.5/1 | 40 | 25 | 18 | 225 | 175 |

| PV1.5* | 40 | 40 | 26 | 225 | 200 |

| PV2* | 50 | 50 | 38 | 300 | 220 |

DRAIN VALVES

| Cat.Ref. | DN | DN1 | d | L | H | D |

|---|---|---|---|---|---|---|

| PVD0.5 | 12 | 12 | 10 | 125 | 125 | 22 |

| PVD0.7 | 15 | 15 | 10 | 125 | 125 | 22 |

| PVD1* | 25 | 25 | 18 | 175 | 175 | 18 |

| PVD1.5/1* | 40 | 25 | 18 | 225 | 175 | 17285 |

| PVD1.5* | 40 | 40 | 26 | 225 | 200 | 42 |

| PVD2* | 50 | 50 | 38 | 300 | 220 | 50 |

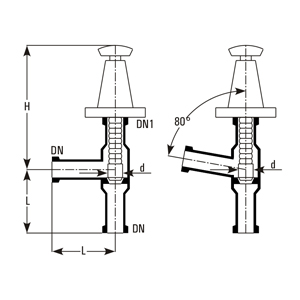

ANGLE VALVES

| Cat.Ref. | DN | DN1 | d | L | H | Degree |

|---|---|---|---|---|---|---|

| PVE0.5 | 12 | 12 | 10 | 50 | 85 | 90 |

| PVE0.7 | 15 | 15 | 10 | 50 | 85 | 90 |

| PVE1* | 25 | 25 | 18 | 100 | 175 | 90 |

| PVE1/80* | 25 | 25 | 18 | 100 | 175 | 80 |

| PVE1.5* | 40 | 40 | 26 | 150 | 200 | 90 |

| PVE2 | 50 | 50 | 38 | 150 | 220 | 90 |

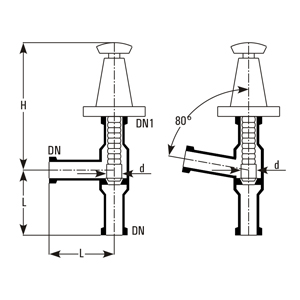

VENT VALVES

| Cat.Ref. | DN | D | d | L | L1 |

|---|---|---|---|---|---|

| PVV0.5 | 12 | 12 | 10 | 125 | 90 |

| PVV0.7* | 15 | 15 | 10 | 125 | 90 |

| PVV1* | 25 | 12 | 10 | 150 | 90 |

| PVV1.5* | 40 | 12 | 10 | 150 | 100 |

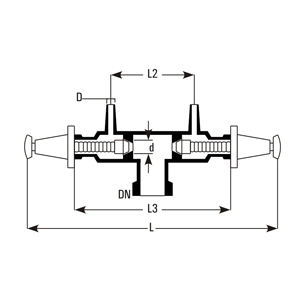

VENT / VACUUM VALVES

| Cat.Ref. | DN | D | d | L | L1 | L2 | L3 |

|---|---|---|---|---|---|---|---|

| PVW 1/0.7* | 25 | 12 | 10 | 280 | 55 | 85 | 160 |

| PVW 1.5/0.7* | 40 | 12 | 10 | 280 | 65 | 85 | 160 |

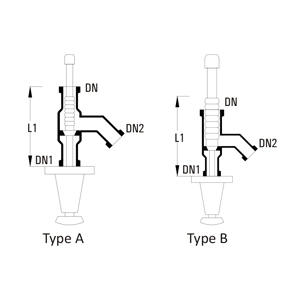

BOTTOM OUTLET VALVES

These valves prevent the accumulation of solids or liquid in the bottom outlet of a vessel. This valve can be incorporated in any spherical or cylindrical vessel

| Cat.Ref. | DN | DN1 | DN2 | L1 | Type |

|---|---|---|---|---|---|

| BAL1* | 25 | 25 | 25 | 150 | A |

| BAL1.5* | 40 | 25 | 25 | 150 | B |

| BAL2 | 50 | 25 | 40 | 150 | B |

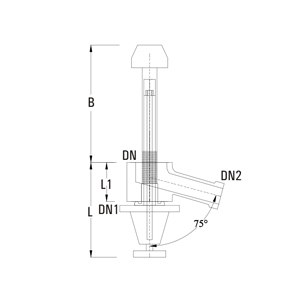

SPACER BOTTOM OUTLET VALVES

| Cat.Ref. | DN | DN1 | L1 | L | B |

|---|---|---|---|---|---|

| SBAL1 | 25 | 15 | 40 | 110 | 175 |

| SBAL1.5 | 50 | 25 | 60 | 160 | 175 |

| SBAL2 | 50 | 25 | 60 | 160 | 175 |

WEIGHT OPERATED PRESSURE RELIEF VALVE

The pressure relief valve (WPRV) is a valve used to control or limit the pressure in a system or vessel which can build up by a process upset, instrument or equipment failure, or fire.

The pressure is relieved by allowing the pressurized gas/fluid to flow out of the system. The pressure relief valve is designed or set to open at a predetermined set pressure to protect Glass vessels and other equipment from being subjected to pressures that exceed their design limits. When the set pressure is exceeded, the pressure relief valve is forced open and a portion of the gas/fluid is released maintaining the required system pressure.

Weight operated pressure relief valve is constructed of glass and PTFE. Sealing of moving parts is effected by a PTFE bellows

The maximum recommended operating temperature is 150 C and a range of pressure as mentioned below.

It should be installed with the spindle vertical and adequate support should be given.

| Model | Size | Pr. range (BAR.g) | Appx. Height (H) | Appx. Width (H1) |

|---|---|---|---|---|

| WPRV-1.5 | DN40 | 0.4/0.7/0.9 | 240mm | 275mm |

| WPRV-2 | DN50 | 0.1/0.2/0.3 | 270mm | 275mm |